Modules

All IASE modules are manufactured from the highest-quality materials. Many are customizable to meet the specific packaging needs of the individual customer. Modules are assembled within modular frames to provide complete system solutions.

WIPTM

IASE’s Wireless Intelligent Positioning Transport Module is composed of a series of modular, linear sections and two cantilevered freely-rotating end sections to assist with carriage management. Multiple section lengths are available to provide for a fully flexible overall length.

The carriages of the WIPTM are fully autonomous and communicate via wireless signal. Each independently controlled carriage is guided by precision linear bearings, enabling swift, quiet, and smooth movement.

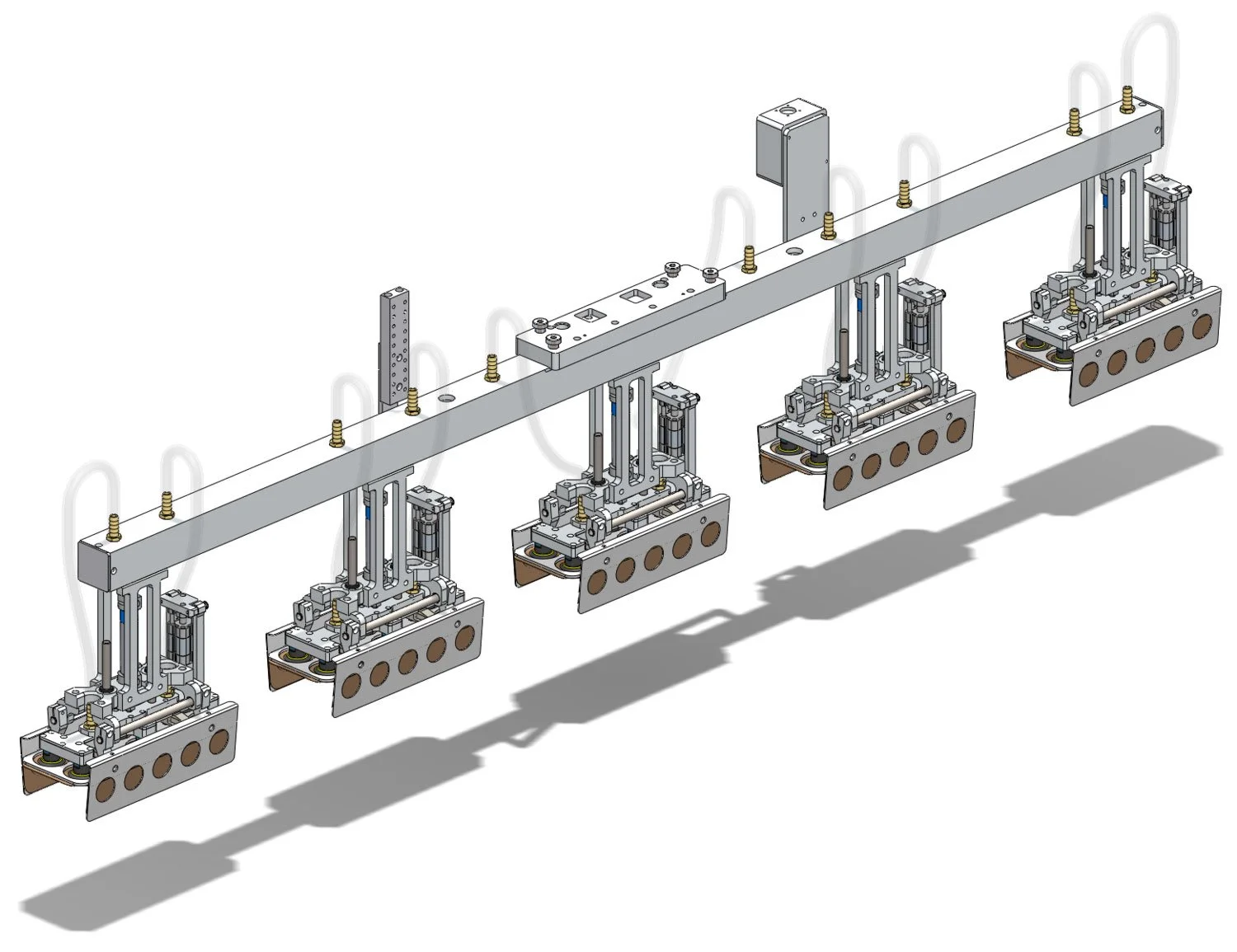

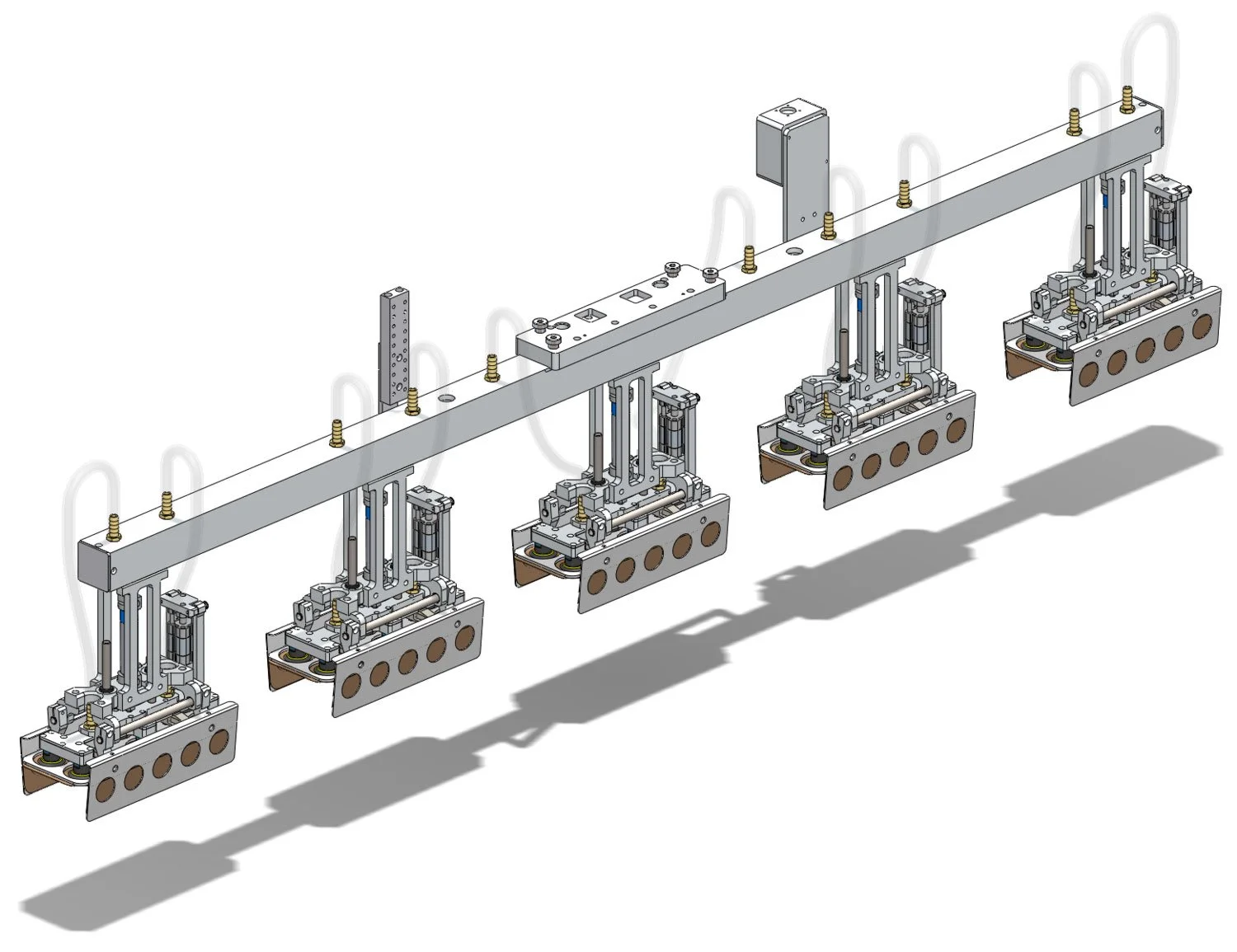

Robotic Hands

Our robotic hands serve a multitude of functions and can be customized to fill most requirements. Some of these functions include, but are not limited to: product handling, folding and placing cardboard inserts, and box closing and transfer.

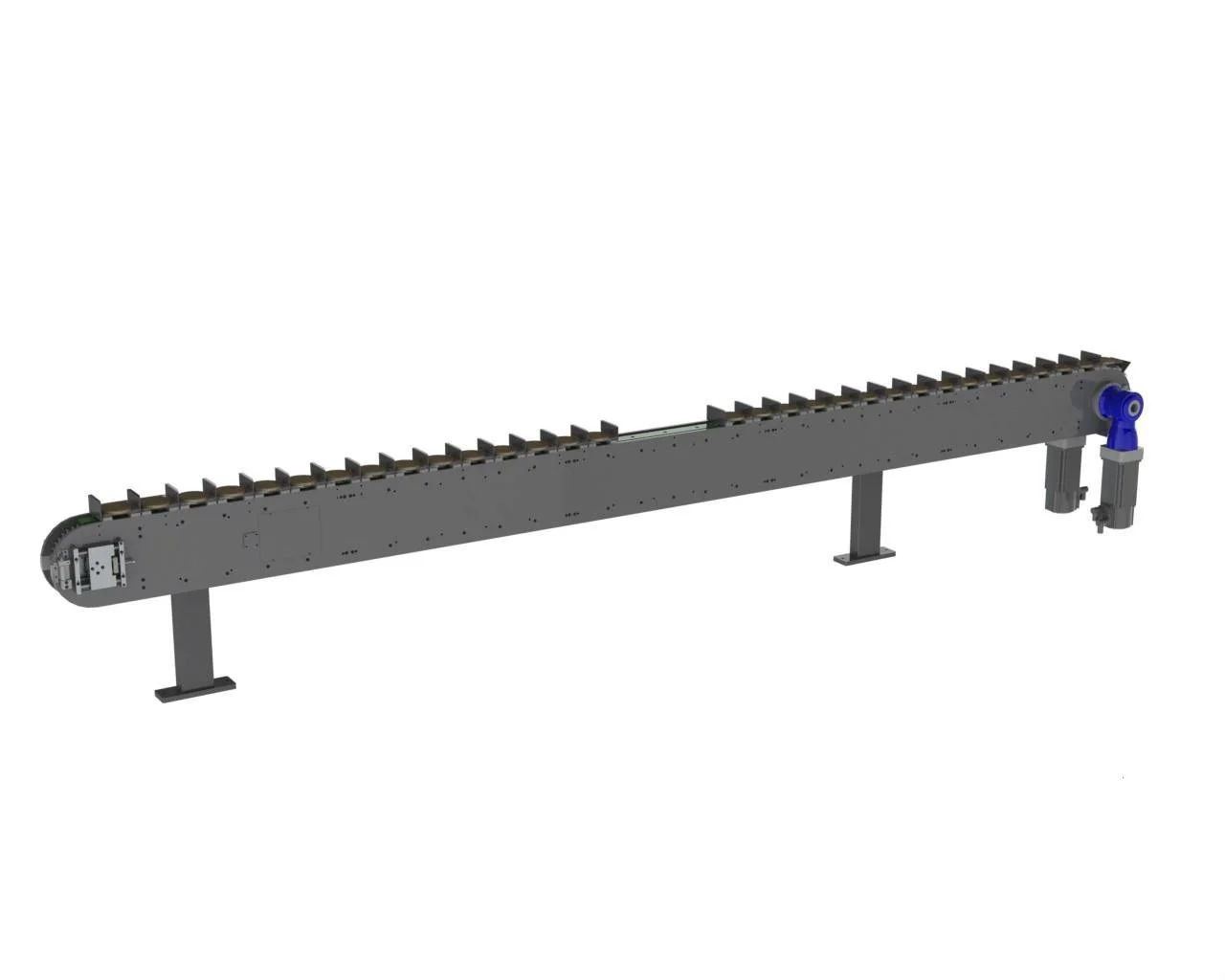

VC-300 Indexer

The VC-300 is a single-axis vertical collator designed to accurately position and convey cartons, trays and cases for various operation. Equipped with quick disconnect mechanisms the cleats can easily be changed to accomodate a large variety of product and carton sizes and configurations.

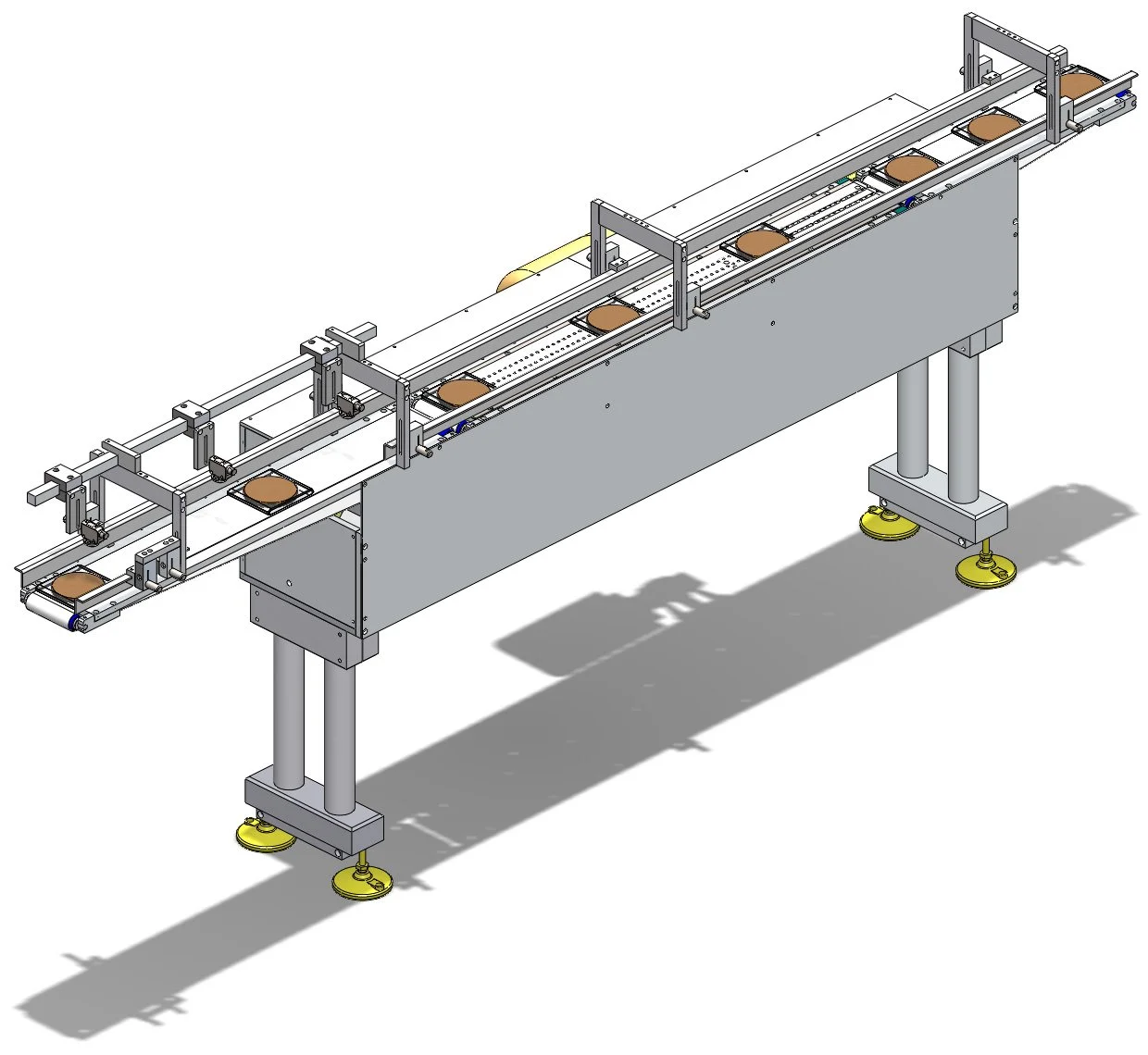

VC-500 Collator

The VC-500 is a two-axis vertical collator designed to position and group products at speeds up to 800 ppm for loading into cartons, trays, and cases. The VC-500 provides continuous motion infeed for multipack packaging or cartoning. Completely toolless changeover allows for quick configuration changes.

Infeed Module

In many cases our infeed, or phasing, modules will be your product's introduction to one of our packaging systems. This module is responsible for accepting products from upstream processes and making sure they reach proper speed and spacing for efficient packaging.

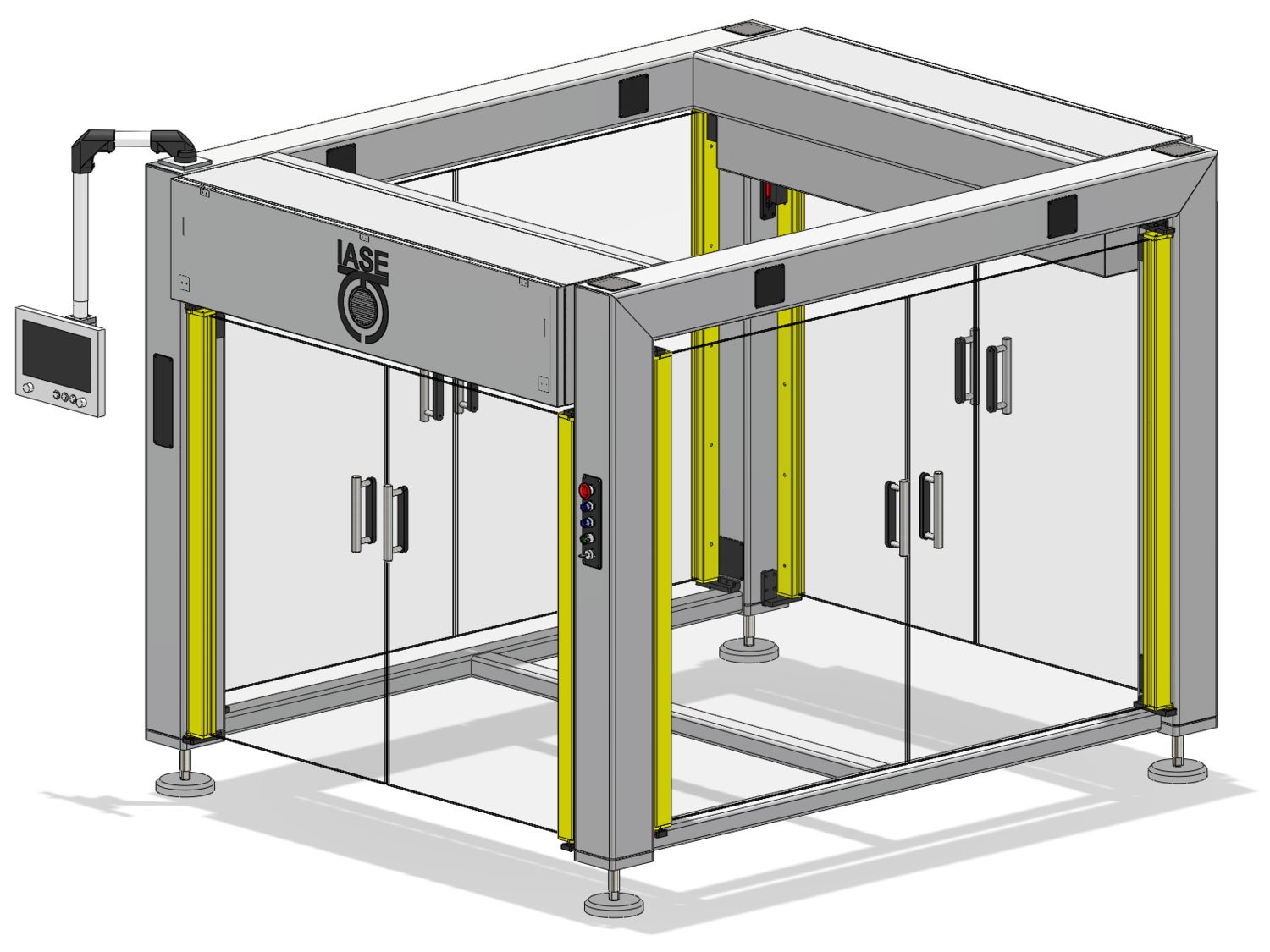

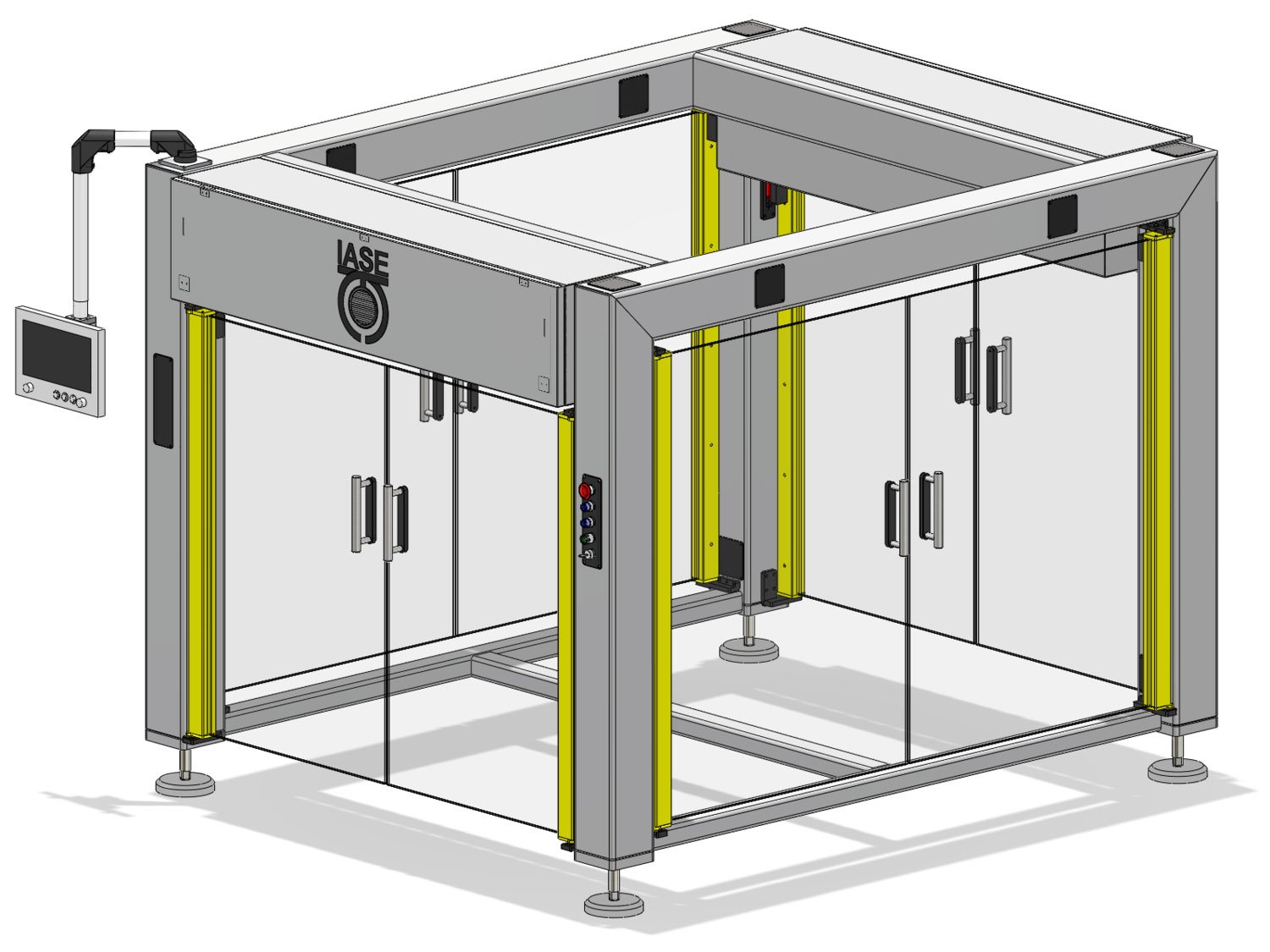

Modular Frame

The IASE modular frame represents a significant innovation in the design of packaging machines, replacing the traditional base plate design that IASE had successfully employed for the past three decades.

With the modular frame, control stations are now embedded in the frame for ease of access and operation. Additional controls, operational settings, and troubleshooting tools are available using the adjustable STRONGARM mounted Human Machine Interface (HMI) with a full, multi-touch screen SCADA package tailored to the customer’s needs. For a cleaner appearance and to maximize machine access, electrical control panels are located in the upper frame. A modular frame packaging system is built with suspended mechatronic modules from our library.

SR-56 2-Axis

The SR-56 is a direct descendant of the traditional R-50 Robot, which was first introduced by IASE in 1986.

The SR-56 combines the dependability of the R-50 with an innovative suspended mount, producing a smaller, cleaner footprint that gives you a competitive edge. Like the R-50 before it, the SR-56 is extremely versatile, performing tasks such as carton forming, product loading, product manipulation, and carton closing.

R-150 Michelangelo

IASE is proud to introduce its latest advancement in automated packaging technology: the R-150 Michelangelo. The first of its kind on the market, Michelangelo is an articulated boom robot with a broad range of motion and complete product rotation, providing IASE customers with competitive performance and durability within a more economic workspace.